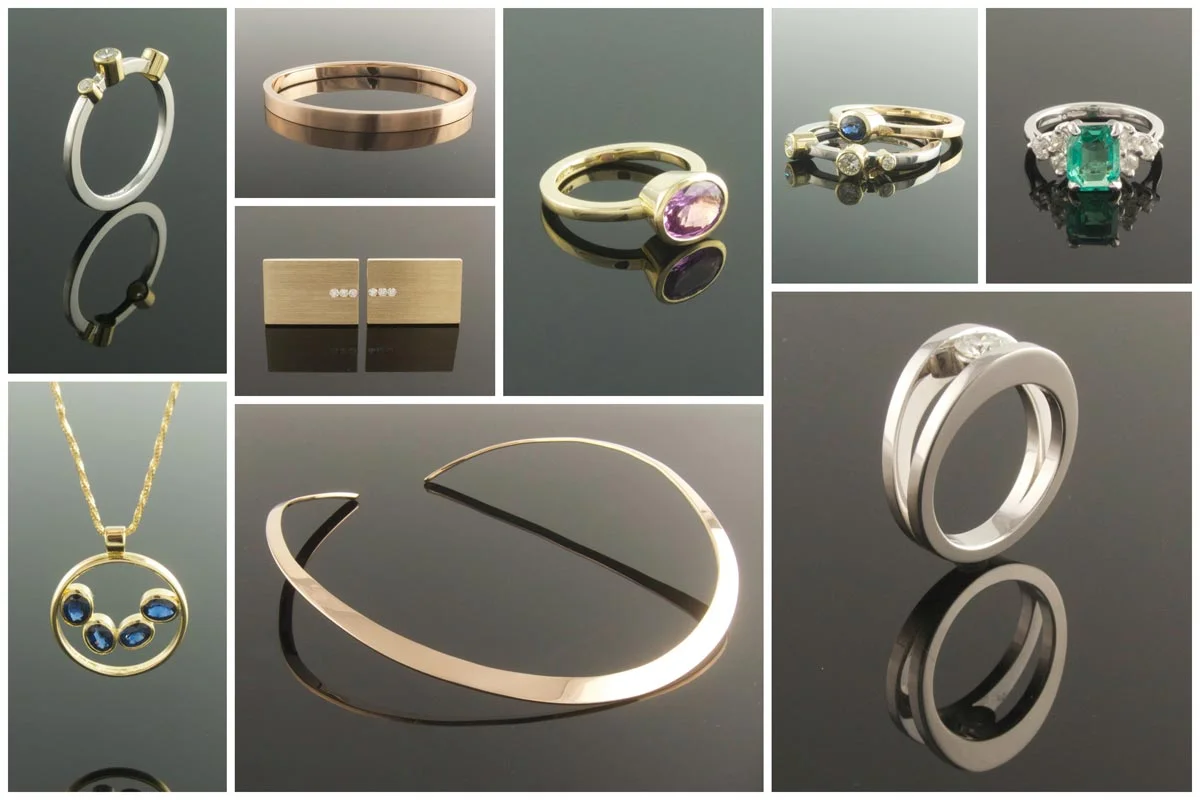

When my sister got married she gave me a few quid to make myself a bridesmaid gift and I thought I'd turn that into a little something for both of us. I bought a length of 9ct yellow gold wire and now we have matching oval gold bangles.

It now turns out that this little bangle is one of the most popular items that I make from recycled gold. Part of the reason is the ease of wear (neither of us ever take them off, not even for airport security) and a bangle is also a cost effective way to use up a good quantity of gold without employing too much labour. That's one of the things about recycling...it would be easier to start with new material, but often times it's more economical or sentimentally sensitive to rework what's already there.

Which brings me to Anne, a friend of my sister's, who had long admired our little bangles. She had a gold gate bracelet that was of huge sentimental value, but which was never worn, so we devised a plan to melt it down and make her her own bangle.